Description

LSA GmbH, as a pioneer, is successfully putting the advantages of laser emission spectrometry into execution in highly automated facilities in production processes of the metalworking industry. The goal is to 100% exclude material grade changes throughout every type of manufacturing process.

Copra uses this innovative technology for the automatic on-line material grade testing of coils in steel-mills.

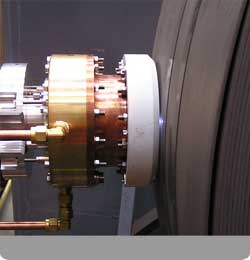

Copra – Coil Testing Unit

Thanks to its outstanding characteristics, steel ensures safety and confidence in end products. Even the smallest discrepancy in the chemical composition can lead to dangerous situations in the use of the product at stability limits and thus to loss of confidence in the product. There is a heightened risk of material grade changes at many places in steel-mills. This risk begins with the further processing of the slab and ends with the incorrect marking of the milled coil. In order to prevent these possible risks, Copra can carry out a fully automatic 100% testing, for example in post production control, and thereby reliably avoid every material grade change.

- Benefits of Copra

- Reliable: Copra is a fully automatic, low maintenance testing unit.

- Safe: Copra tests every coil for material grade changes, for example in post production control. Even with hundreds of different alloys and with different coil sizes, Copra automatically identifies the optimal test point.

- Integration: thanks to measurement capable of functioning in real time, Copra can be integrated into an assembly line. There is no need for sample preparation; scale layers can be removed on site by laser.

- Non-destructive: by means of the laser supported element analysis, Copra vaporises only the slightest traces of the material.